PDR techniques offer a non-invasive, eco-friendly way to repair minor vehicle dents without repainting. Technicians assess damage, then use specialized tools to reshape metal and fuse gaps, preserving the original factory finish. This method is faster, cheaper, and less environmentally harmful than traditional repainting, making it a preferred choice for auto repair shops. PDR is effective for collision damage, including fender benders, and preserves the historical integrity of classic or vintage vehicles.

Discover the revolutionary power of PDR techniques in restoring damaged car panels without repainting. This advanced method offers a precise, cost-effective alternative to traditional repair processes. In this article, we demystify the science behind PDR, outlining its step-by-step process and showcasing its numerous benefits through real-world success stories. Learn how PDR techniques are transforming panel restoration, ensuring vehicles return to their original condition with minimal impact on the environment and your wallet.

- Understanding Panel Damage Restoration (PDR) Techniques

- The Step-by-Step Process of PDR without Repainting

- Benefits and Success Stories of PDR for Panel Restoration

Understanding Panel Damage Restoration (PDR) Techniques

Panel Damage Restoration (PDR) techniques are a set of specialized methods used to repair and restore damaged vehicle panels without the need for repainting. This process is particularly valuable for auto collision centers and car repair shops dealing with minor dents, dings, and creases often caused by fender benders or other light impacts. PDR involves several steps: first, assessing the damage to determine its severity and suitability for restoration. If the panel is bendable but not broken, technicians use specialized tools to carefully adjust and realign the metal, returning it to its original shape. This process, known as “pulling” or “pinning,” requires precision and expertise to avoid further damage.

Once the panel is correctly aligned, other techniques like plastic welding or heat activation may be employed to fuse any gaps or seams. The result is a restored panel that matches the vehicle’s original finish seamlessly. PDR offers significant advantages over traditional repainting methods, including faster turnaround times, cost savings for both customers and auto repair shops, and minimal environmental impact. This eco-friendly approach not only reduces waste but also preserves the original factory finish of the vehicle, making it a preferred choice in many quality-conscious car repair shops.

The Step-by-Step Process of PDR without Repainting

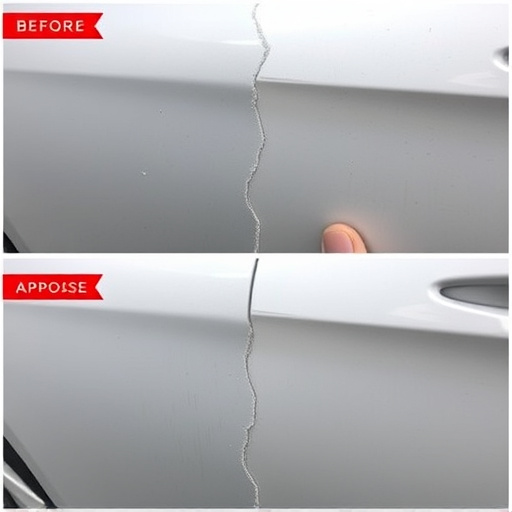

The process of restoring panels without repainting using PDR (Paintless Dent Repair) techniques involves several precise steps. It begins with a thorough inspection of the damaged area to assess the extent of the dent or crunch. Skilled technicians then use specialized tools, such as metal sliders and plastic tools, to carefully manipulate and adjust the panel back to its original shape without disturbing the surrounding paint.

Next, they apply a combination of pressure and heat using these tools, working slowly and precisely to ensure the panel returns to its correct contour. This meticulous process avoids any need for sanding or additional priming, preserving the original factory finish. Once the dent is completely eliminated, the area is inspected again to confirm perfection before proceeding with other body shop services like final polishing if required. This collision repair method not only saves time and costs but also ensures a seamless, unnoticeable restoration, maintaining the vehicle’s aesthetic appeal.

Benefits and Success Stories of PDR for Panel Restoration

PDR techniques offer a multitude of benefits for panel restoration, making it a preferred choice over repainting in many cases. One of the primary advantages is its cost-effectiveness; PDR is significantly less expensive than full repainting, saving both time and money for car owners. This non-invasive method also preserves the original factory finish, ensuring that the car retains its value and aesthetic appeal.

Numerous success stories highlight the effectiveness of PDR in repairing car collision damage, including fender benders. By expertly restoring panels to their pre-accident condition, PDR technicians avoid unnecessary material removal and preservation of the existing paint. This not only reduces costs but also preserves the historical integrity of classic or vintage vehicles. Car owners often report impressive results, with damaged areas looking virtually undetectable after PDR treatment, showcasing the technique’s versatility and success in various scenarios.

PDR techniques offer a revolutionary approach to panel restoration, eliminating the need for repainting. By understanding the process and its benefits, we can appreciate how these methods restore damaged panels to their original state efficiently and cost-effectively. The step-by-step process detailed in this article highlights PDR’s versatility and success stories bear witness to its transformative power. Adopting PDR techniques not only conserves resources but also contributes to a more sustainable future, making it the preferred choice for panel restoration in today’s automotive industry.